Spreader type

Single Lift

Twin Lift

long-Twin

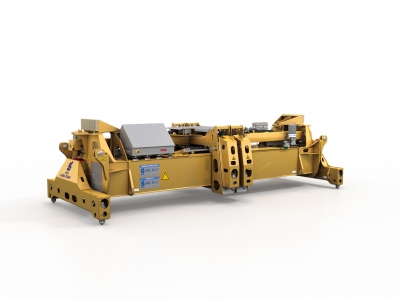

Straddle Carrier Spreaders features

Optimized Visibility

Our monobeam constructions allows for a slim midframe that gives your operators optimal sight lines on the container and its surroundings, while your technicians have easy access during maintenance.

Cylinder

Telescopic System

A strong hydraulic cylinder based telescoping system telescopes the mono-beams in and out of the midframe. The cylinder is fast, produces little noise and requires no lubrication.

Collision Protection

A mechanical blocking device driven by a hydraulic cylinder is mounted outside the midframe to absorb horizontal forces on the end beam during collision with a container. It also secures spreader telescoping positions.

Gap Detection System

The gap detection system is a security system to prevent the spreader from locking in single mode on two (2) 20ft. containers.

Patented Twistlock

Design

The twistlock is one of the most critical components of your spreader. Our patented double collar twistlock design provides the longest possible life span for your twistlocks and allows for easy removal of the twistlock nut for non-destructive testing.

Dampening

brackets

Our straddle carrier spreader are equipped with a dampening bracket to limit the spreader damage while moving with a loaded carrier.

Landing

pin

Our spreaders are equipped with a landing pin on the side of each twistlock of the spreader. All landing pins have to be individually raised to enable the twistlocks to lock/unlock.

Automatic Greasing System

Our automatic greasing system can service up to 50 greasing points on your spreader. The system guarantees consistent spreader performance and reduces wear and tear. You see this returned as less downtime and lower maintenance cost.

DRIVEN BY SUCCESS

Straddle Carrier Spreaders Options

LED Lights

Dimmable

Our spreaders can be equipped with dimmable LED lights. Several options are available to enhance safety.

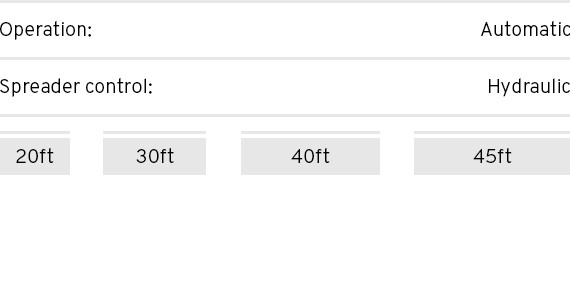

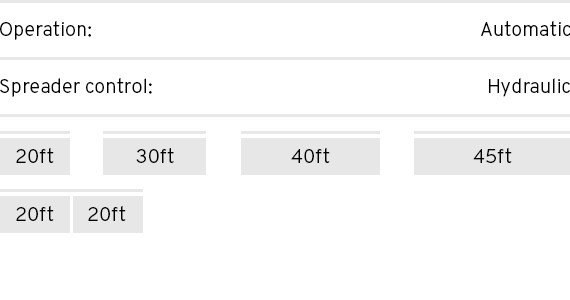

Automatic

Positioning System

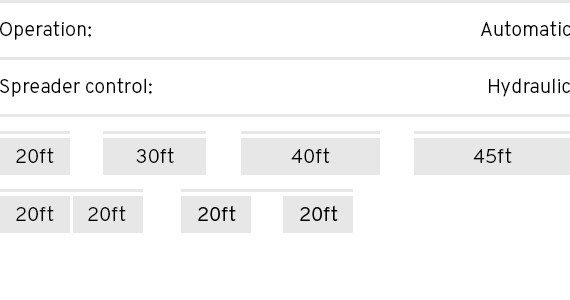

Automatic Positioning System adjusts the length and width of the spreader. Complete APS consists of multiple sensors which are mounted on the end beams. APS ensures smooth and fast aligning off the spreader on the container.

Working Lights At

The Twistlocks

Time pressure leaves no room for error, let alone accidents. To increase productivity and for safety purposes, LED lights can be installed at the twistlocks to see the twistlock status.

Safety

Striping

It’s possible to fully customize our lifting equipment. Striping is often used as a safety option that shows the moving elements.

Safety Lugs

Or Hooks

Four (4) lifting lugs or hooks with each a capacity of 10t can be installed next to the twistlocks for vertical lifting of

Height indication

system

The Height Indication System consists of a proximity switch (reach 0.8 – 6 meter) with 1 or 2 set-points, to measure the distance between the underside of the spreader and the top of the container. This system allows you to reduce the landing speed when approaching the container.

Lock/Unlock Flags

On The Twistlocks

The red elements on the top of the twistlocks are a very good solution to see whether the twistlocks are locked or unlocked. This option can increase crane productivity.

Overheight

Brackets

Four (4) brackets can be installed on the endbeams of your spreader to connect various brands of overheight frames, thus improving the versatility of the spreader.

Safety

Stops

Our spreader is equipped with three safety stops to stop the spreader at any given time: one on the E-box and one on either side of the midframe. By pressing any one of these safety stops the spreader stops operating. On request more safety stops can be on the spreader for extra safety.

Snow

Endbeam

The snow end beam is a useful option for terminals that experience snow, sand or debris on containers. Instead of needing to clear the whole container, it removes snow, sand and debris from around the corner castings. IThis results in smoother operation and could extend the lifetime of your spreader end beam.

Roof Detection

System

In addition to the gap detection system, and optional roof detection system can be installed on your spreader. These sensors detect container tops. This completes a full Twin Twenty Detection System for safe operation.

Double Gap

Detection System

Our straddle carrier spreaders are equipped as standard with a single gap detection system. Adding a second gap detection sensor makes it possible to detect misaligned containers more accurately.

A BETTER WAY FORWARD

AT YOUR SERVICE

Our dedicated specialists travel to your site to troubleshoot your equipment whenever you need them. If you prefer to let your own staff do the work, we can provide a thorough analysis and will support your technicians from afar.

SPREADER TYPE

SINGLE LIFT

twin lift

long-twin

Straddle Carrier Spreaders Features

Our monobeam constructions allows for a slim midframe that gives your operators optimal sight lines on the container and its surroundings, while your technicians have easy access during maintenance.

Optimized visibility

A strong hydraulic cylinder based telescoping system telescopes the mono-beams in and out of the midframe. The cylinder is fast, produces little noise and requires no lubrication.

Cylinder Telescopic System

A mechanical blocking device driven by a hydraulic cylinder is mounted outside the midframe to absorb horizontal forces on the end beam during collision with a container. It also secures spreader telescoping positions.

Collision Protection

The gap detection system detects the gap in between two 20 ft. containers and works as a security system to prevent the spreader from locking in single mode.

Gap Detection System

The twistlock is one of the most critical components of your spreader. Our patented double collar twistlock design provides the longest possible life span for your twistlocks and allows for easy removal of the twistlock nut for non-destructive testing.

Patented Twistlock Design

Our straddle carrier spreaders are equipped with a dampening bracket to limit the spreader damage and reduces the noise while moving with a loaded carrier.

Dampening brackets

Our spreaders are equipped with a landing pin on the side of each twistlock of the spreader. All landing pins have to be individually raised to enable the twistlocks to lock/unlock.

Landing pin

Our automatic greasing system can service up to 50 greasing points on your spreader. The system guarantees consistent spreader performance and reduces wear and tear. You see this returned as less downtime and lower maintenance cost.

Automatic Greasing System

SUCCESS

Straddle Carrier Spreaders Options

Our spreaders can be equipped with dimmable LED lights. Several options are available to enhance safety.

LED Lights Dimmable

Automatic Positioning System adjusts the length and width of the spreader. Complete APS consists of multiple sensors which are mounted on the end beams. APS ensures smooth and fast aligning off the spreader on the container.

automatic positioning system

Time pressure leaves no room for error, let alone accidents. To increase productivity and for safety purposes, LED lights can be installed at the twistlocks to see the twistlock status.

Working Lights

It’s possible to fully customize our lifting equipment. Striping is often used as a safety option that shows the moving elements.

Safety Striping

Four (4) lifting lugs or hooks with each a capacity of 10t can be installed next to the twistlocks for vertical lifting of

Safety Lugs Or Hooks

The Height Indication System consists of a proximity switch (reach 0.8 – 6 meter) with 1 or 2 set-points, to measure the distance between the underside of the spreader and the top of the container. This system allows you to reduce the landing speed when approaching the container.

Height Indication System

The red elements on the top of the twistlocks are a very good solution to see whether the twistlocks are locked or unlocked. This option can increase crane productivity.

Lock/Unlock Flags

Four (4) brackets can be installed on the endbeams of your spreader to connect various brands of overheight frames, thus improving the versatility of the spreader.

OVERHEIGHT BRACKETS

Our spreader is equipped with three safety stops to stop the spreader at any given time: one on the E-box and one on either side of the midframe. By pressing any one of these safety stops the spreader stops operating. On request more safety stops can be on the spreader for extra safety.

Safety Stops

The snow end beam is a useful option for terminals that experience snow, sand or debris on containers. Instead of needing to clear the whole container, it removes snow, sand and debris from around the corner castings. This results in smoother operation and could extend the lifetime of your end beam.

Snow endbeam

In addition to the gap detection system, and optional roof detection system can be installed on your spreader. These sensors detect container tops. This completes a full Twin Twenty Detection System for safe operation.

Roof Detection System

Our straddle carrier spreaders are equipped as standard with a single gap detection system. Adding a second gap detection sensor makes it possible to detect misaligned containers more accurately.

Double Gap Detection System

FORWARD

AT YOUR SERVICE

Our dedicated specialists travel to your site to troubleshoot your equipment whenever you need them. If you prefer to let your own staff do the work, we can provide a thorough analysis and will support your technicians from afar.

Spreader type

Single lift

Twin Lift

Long-twin

Straddle Carrier Spreaders features

Our monobeam constructions allows for a slim midframe that gives your operators optimal sight lines on the container and its surroundings, while your technicians have easy access during maintenance.

Optimized Visibility

Optimized Visibility

A strong hydraulic cylinder based telescoping system telescopes the mono-beams in and out of the midframe. The cylinder is fast, produces little noise and requires no lubrication.

Cylinder Telescopic System

Cylinder Telescopic System

A mechanical blocking device driven by a hydraulic cylinder is mounted outside the midframe to absorb horizontal forces on the end beam during collision with a container. It also secures spreader telescoping positions.

Collision Protection

Collision Protection

The gap detection system is a security system to prevent the spreader from locking in single mode on two (2) 20ft. containers.

Gap Detection System

Gap Detection System

The twistlock is one of the most critical components of your spreader. Our patented double collar twistlock design provides the longest possible life span for your twistlocks and allows for easy removal of the twistlock nut for non-destructive testing.

Patented Twistlock Design

Patented Twistlock Design

Our straddle carrier spreader are equipped with a dampening bracket to limit the spreader damage while moving with a loaded carrier.

Dampening brackets

Dampening Brackets

Our spreaders are equipped with a landing pin on the side of each twistlock of the spreader. All landing pins have to be individually raised to enable the twistlocks to lock/unlock.

Landing Pin

Landing Pin

Our automatic greasing system can service up to 50 greasing points on your spreader. The system guarantees consistent spreader performance and reduces wear and tear. You see this returned as less downtime and lower maintenance cost.

Automatic greasing system

Automatic Greasing System

DRIVEN BY SUCCESS

Straddle Carrier Spreaders Options

Our spreaders can be equipped with dimmable LED lights. Several options are available to enhance safety.

LED Lights Dimmable

LED Lights Dimmable

Automatic Positioning System adjusts the length and width of the spreader. Complete APS consists of multiple sensors which are mounted on the end beams. APS ensures smooth and fast aligning off the spreader on the container.

Automatic Positioning System

Automatic Positioning System

Time pressure leaves no room for error, let alone accidents. To increase productivity and for safety purposes, LED lights can be installed at the twistlocks to see the twistlock status.

Working Lights At The Twistlocks

Working Lights at the Twistlocks

It’s possible to fully customize our lifting equipment. Striping is often used as a safety option that shows the moving elements.

Safety Striping

Safety Striping

Four (4) lifting lugs or hooks with each a capacity of 10t can be installed next to the twistlocks for vertical lifting of

Safety Lugs Or Hooks

Safety Lugs Or Hooks

The Height Indication System consists of a proximity switch (reach 0.8 – 6 meter) with 1 or 2 set-points, to measure the distance between the underside of the spreader and the top of the container. This system allows you to reduce the landing speed when approaching the container.

Height indication system

Height Indication System

The red elements on the top of the twistlocks are a very good solution to see whether the twistlocks are locked or unlocked. This option can increase crane productivity.

Lock/Unlock Flags On The Twistlocks

Lock/Unlock Flags

Four (4) brackets can be installed on the endbeams of your spreader to connect various brands of overheight frames, thus improving the versatility of the spreader.

Overheight Brackets

Overheight Brackets

Our spreader is equipped with three safety stops to stop the spreader at any given time: one on the E-box and one on either side of the midframe. By pressing any one of these safety stops the spreader stops operating. On request more safety stops can be on the spreader for extra safety.

Safety Stops

Safety Stops

The snow end beam is a useful option for terminals that experience snow, sand or debris on containers. Instead of needing to clear the whole container, it removes snow, sand and debris from around the corner castings. IThis results in smoother operation and could extend the lifetime of your spreader end beam.

Snow Endbeam

Snow Endbeam

In addition to the gap detection system, and optional roof detection system can be installed on your spreader. These sensors detect container tops. This completes a full Twin Twenty Detection System for safe operation.

Roof Detection System

Roof Detection System

Our straddle carrier spreaders are equipped as standard with a single gap detection system. Adding a second gap detection sensor makes it possible to detect misaligned containers more accurately.

Double Gap Detection System

Double Gap Detection System