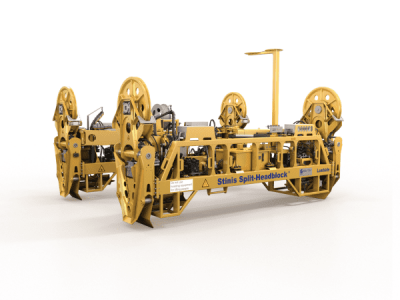

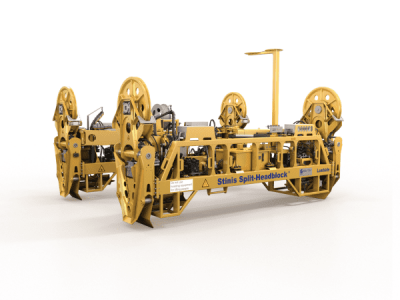

Spreader type

Stinis Split-Headblock®

Stinis Split-Headblock® features

LED Lights Dimmable

Our Split-Headblock is standard equipped with dimmable LED lights. Several options are available to enhance safety. Red or green indicate the lock or unlock signal and the white lights shows if a spreader is landed correctly.

Automatic

Connector

Save time and effort by automatically connecting the Stinis Split-Headblock to the spreaders. Electric power, data signals & hydraulic fluids can be passed between SSH & spreaders through the automatic connector.

Automatic Greasing System

Our automatic greasing system can service up to 80 greasing points on your Stinis Split-Headblock. The system guarantees consistent SSH performance and reduces wear and tear. You see this returned as less downtime and lower maintenance cost.

Pin

Connection

The four-pin set-up of the Stinis Split-Headblock can automatically connect spreaders in single or tandem mode without the use of manpower. The sensors detect when the SSH is landed on either one or two spreaders and will give a signal to make the pins move.

POWERED BY INNOVATION

Stinis Split-Headblock® Movements

LIST

Explained

The list function can be used in passive mode. This allows the spreaders to float freely to pick up containers that are positioned on an angle. Once containers are lifted, Active listing is needed to balance eccentrically loaded containers.

Offset

Explained

The arms of the SSH can rotate under an angle of 30 degrees to create a vertical offset between the two spreaders of up to 1115mm. This allows the crane operator to handle two containers that are positioned at different heights, or change from tandem to single mode with one spreader positioned on a trailer and the other on the ground.

Skew

Explained

Changing the position of the sheave boxes (e.g. skewing) will move the spreaders back into a straight line when the containers are carried by wind. This will shorten the time needed to position the containers inside the ship’s cell guides or in a straight line on the crane platform, quayside or on trailers.

Translate

Explained

Translation allows variation in the position of the spreader in the longitudinal direction. If trailers or containers are placed in an offset position, the headblock is able to compensate for this offset.

Trim

Explained

Spreaders can get stuck in a ship’s cell guides. Containers can also be placed on trailers on an angle by the crane operator. The trim function prevents the Stinis Split-Headblock from getting damaged in these situations.

Separation Explained

The arms of the SSH can separate the two connected spreaders to create a distance between the containers of up to 1600mm. This allows for fast and efficient trailer, AGV, straddle carrier and ship cell operation. The distance can be stored with a set point to further automate the loading/unloading process.

EXPLORE THE MOVEMENTS

AT YOUR SERVICE

Our dedicated specialists travel to your site to troubleshoot your equipment whenever you need them. If you prefer to let your own staff do the work, we can provide a thorough analysis and will support your technicians from afar.

Stinis Split-Headblock® features

Our Split-Headblock is standard equipped with dimmable LED lights. Several options are available to enhance safety. Red or green indicate the lock or unlock signal and the white lights shows if a spreader is landed correctly.

LED Lights Dimmable

Save time and effort by automatically connecting the Stinis Split-Headblock to the spreaders. Electric power, data signals & hydraulic fluids can be passed between SSH & spreaders through the automatic connector.

Automatic Connector

Our automatic greasing system can service up to 80 greasing points on your spreader. The system guarantees consistent spreader performance and reduces wear and tear. You see this returned as less downtime and lower maintenance cost.

Automatic greasing system

The four-pin set-up of the Stinis Split-Headblock can automatically connect spreaders in single or tandem mode without the use of manpower. The sensors detect when the SSH is landed on either one or two spreaders and will give a signal to make the pins move.

Pin Connection

INNOVATION

Stinis Split-Headblock® Movements

The list function can be used in passive mode. This allows the spreaders to float freely to pick up containers that are positioned on an angle. Once containers are lifted, Active listing is needed to balance eccentrically loaded containers.

LIST Explained

OFFSET Explained

The arms of the SSH can rotate under an angle of 30 degrees to create a vertical offset between the two spreaders of up to 1115mm. This allows the crane operator to handle two containers that are positioned at different heights, or change from tandem to single mode.

Changing the position of the sheave boxes (e.g. skewing) will move the spreaders back into a straight line when the containers are carried by wind. This will shorten the time needed to position the containers inside the ship’s cell guides or in a straight line on the crane platform, quayside or on trailers.

Skew Explained

Translate Explained

Translation allows variation in the position of the spreader in the longitudinal direction. If trailers or containers are placed in an offset position, the headblock is able to compensate for this offset.

Trim Explained

Spreaders can get stuck in a ship’s cell guides. Containers can also be placed on trailers on an angle by the crane operator. The trim function prevents the Stinis Split-Headblock from getting damaged in these situations.

Separation Explained

The arms of the SSH can separate the two connected spreaders to create a distance between the containers of up to 1600mm. This allows for fast and efficient trailer, AGV, straddle carrier and ship cell operation. The distance can be stored to further automate the loading/unloading process.

MOVEMENTS

AT YOUR SERVICE

Our dedicated specialists travel to your site to troubleshoot your equipment whenever you need them. If you prefer to let your own staff do the work, we can provide a thorough analysis and will support your technicians from afar.

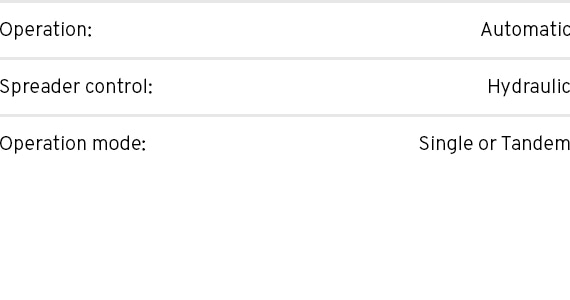

Spreader type

Stinis Split-Headblock®

Stinis Split-Headblock® features

Our Split-Headblock is standard equipped with dimmable LED lights. Several options are available to enhance safety. Red or green indicate the lock or unlock signal and the white lights shows if a spreader is landed correctly.

LED Lights Dimmable

LED Lights Dimmable

Save time and effort by automatically connecting the Stinis Split-Headblock to the spreaders. Electric power, data signals & hydraulic fluids can be passed between SSH & spreaders through the automatic connector.

Automatic Connector

Automatic Connector

Our automatic greasing system can service up to 80 greasing points on your Stinis Split-Headblock. The system guarantees consistent SSH performance and reduces wear and tear. You see this returned as less downtime and lower maintenance cost.

Automatic Greasing System

Automatic Greasing

The four-pin set-up of the Stinis Split-Headblock can automatically connect spreaders in single or tandem mode without the use of manpower. The sensors detect when the SSH is landed on either one or two spreaders and will give a signal to make the pins move.

Pin Connection

Pin Connection

POWERED BY INNOVATION

Stinis Split-Headblock® Movements

The list function can be used in passive mode. This allows the spreaders to float freely to pick up containers that are positioned on an angle. Once containers are lifted, Active listing is needed to balance eccentrically loaded containers.

LIST Explained

The arms of the SSH can rotate under an angle of 30 degrees to create a vertical offset between the two spreaders of up to 1115mm. This allows the crane operator to handle two containers that are positioned at different heights, or change from tandem to single mode with one spreader positioned on a trailer and the other on the ground.

Offset Explained

Changing the position of the sheave boxes (e.g. skewing) will move the spreaders back into a straight line when the containers are carried by wind. This will shorten the time needed to position the containers inside the ship’s cell guides or in a straight line on the crane platform, quayside or on trailers.

Skew Explained

Translation allows variation in the position of the spreader in the longitudinal direction. If trailers or containers are placed in an offset position, the headblock is able to compensate for this offset.

Translate Explained

Spreaders can get stuck in a ship’s cell guides. Containers can also be placed on trailers on an angle by the crane operator. The trim function prevents the Stinis Split-Headblock from getting damaged in these situations.

Trim Explained

The arms of the SSH can separate the two connected spreaders to create a distance between the containers of up to 1600mm. This allows for fast and efficient trailer, AGV, straddle carrier and ship cell operation. The distance can be stored with a set point to further automate the loading/unloading process.

Separation Explained